Project Description

In 2008, Truro opened Cornwall’s first permanent park and ride facility to reduce the traffic congestion in the city. Traffic however continued to build and reached 200 cars per day passing through the city to get to the West Park & Ride installation, causing further congestion.

Cornwall County Council therefore developed the Truro East Park and Ride facility, creating 1,800 car parking spaces as part of a £9.6M regeneration scheme.

The Challenge

As with the original scheme, the design focused on the importance of sustainability and enhancing/protecting the local habitat and landscape.

Planning limitations meant that the run-off from the site could not exceed pre-development levels. Cornwall County Council decided to meet this requirement in part though porous paving. Recognising the significant strains imposed on cellular pavers by coach trafficking, the client identified a requirement for a permeable paver system that can cope with frequent overrun by coaches and resist the forces exerted by heavy vehicles turning and manoeuvring.

The Solution

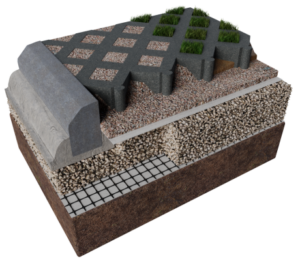

Truckcell 80 porous paver was chosen as the heavy duty surfacing solution for discrete bus turning / parking areas, with the Terrex NW9 geotextile providing a combined separation and treatment function for the run-off.

Truckcell permeable grids satisfied the planning requirement for a natural finish to the surfacing and allows effective stormwater treatment within the subbase, whilst also reducing the overall depth of construction.

ABG Truckcell with gravel or grass infill, overlaying sand and ABG Terrex geotextile

Truckcell permeable paving system is a highly effective source control system that manages stormwater run-off in accordance with best practice guidance. A cost effective, SuDS compliant porous paving solution that facilitates rapid installation, Truckcell pavers are manufactured from 100% recycled, and recyclable, plastics and are proven to withstand frequent overrun by HGVs, trucks, coaches, refuse vehicles and fire engines etc. Weighing only 9kgs per paver, Truckcell easily complies with safe manual handling recommendations.

The ABG Service

ABG provided support to all parties to ensure Truckcell offered the right solution for this site. Design advice on edge detailing, jointing, surface friction and subsurface buildup helped solve some challenging technical queries and meet the planning constraints.

Deliveries to site were coordinated with the project program to be on time without taking up site compound storage space.

Contact ABG today to discuss your permeable paving project requirements and discover how ABG’s past experience and innovative products can help.