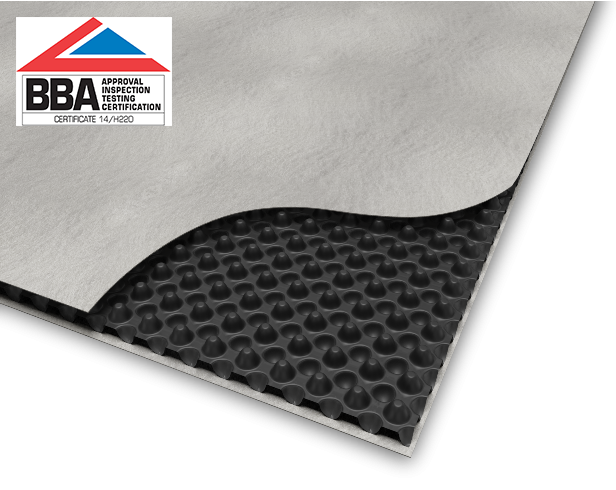

Fildrain drainage geocomposite for civil engineering earthworks and embankment consolidation is a cost-effective alternative to traditional stone drainage systems, collecting and channeling water or gases to a suitable drainage point.

Fildrain’s unique drainage core replaces the requirement for stone filter layers, providing superior flow horizontally and vertically. The filter geotextile prevents clogging of the core.

Fildrain – Earthworks & Embankments

Applications

- Embankment starter layers

- Embankment drainage

- Combined surface and sub-surface drainage

- Embankment basal and consolidation layer

- Embankment counterfort drainage

Benefits

- Cost effective

- High water flows compared to traditional drainage stone

- Re-use of site won excavated material

- Reduction or elimination of drainage stone

- Speed up consolidation

- Rapid installation

- Allows water flow in all directions

- Reduction in haulage requirements

Drainage is a major consideration in all civil engineering earthworks, embankment and slope projects. Sub-surface drainage using a horizontal layer of Fildrain drainage geocomposite replaces the need for granular starter layers, as well as relieving pore pressure and accelerating consolidation. Sub-surface drainage options have been limited to traditional crushed stone filter drains, even though more modern alternatives are available. The Fildrain geocomposite option enables greater use of site won, as-dug materials and this in turn minimises the number of vehicle journeys, both delivering and removing materials from site.

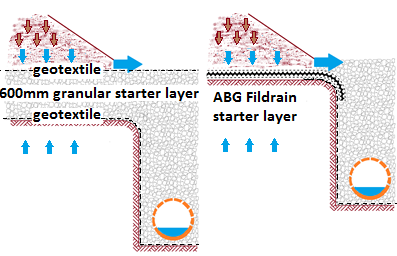

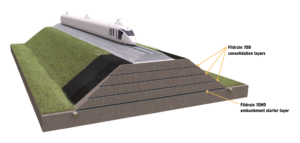

Embankment Starter Layers

A thick granular drainage layer is often placed onto the prepared formation before construction of an embankment. This layer serves two functions, one of which is drainage, and the other is to protect the formation from heavy construction machines. Introducing Fildrain 7DD/ST170 or 7DHD/ST170 will provide the required drainage capacity, this would be overlaid with at least 300mm of fill before tracking with construction plant.

Fildrain geocomposite drainage layer is laid across the width of the embankment and the backfill is placed on the advancing face. The geocomposite must have sufficient compressive strength/flow for the forces generated under the full height of the embankment, and ideally have a core with a central barrier that protects the formation from water ingress and re-hydration due to rainfall.

Consolidation Layers

Earthworks are usually on the critical path when programming project works, and soft soil embankments are no exception. The speed of construction of the embankment depends on the rate at which the pore water pressure can dissipate as the embankment height progresses. Fildrain geocomposite is so effective at reducing pore pressures that it significantly increases the range of soils that can be considered as suitable fill. Even very wet soils that would be unsuitable for use with granular drainage layers may be considered usable.

Fildrain geocomposite has a central impermeable core to restrict the vertical movement of water, which means that each layer of Fildrain acts as a roof to the fill below, preventing rainfall from slowing consolidation. Consequently the weather window for earthworks is extended. Using Fildrain instead of crushed stone also utilises more site won fill, which is cost saving and has a positive impact on the earthworks balance.

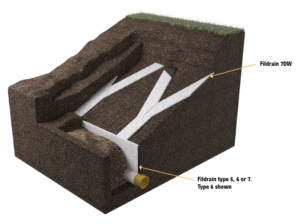

Slope drainage

Slope drainage is primarily required to collect seepage water that emerges from permeable layers in soil slopes, or from open joints in rock slopes. It is there essentially to stop topsoil from slumping or being eroded by water from below.

When designing and constructing cuttings, the ground water level is reduced below the intended surface of the cutting slopes. Traditionally this is achieved with crushed stone counterfort drainage trenches. Installing any trench on a steep slope is not easy. Fildrain helps to make the process simple, in one of three ways:

- Fildrain is installed upright in narrow trenches

- Fildrain is laid flat in strips before the topsoil layer is placed

- Fildrain is laid across the whole area before the topsoil is placed

In addition to new build, Fildrain is excellent for dealing with seepage that has appeared on existing slope cuttings.

Typical Client Profile

- Drainage Contractors

- Water Companies

- Covered Reservoir Engineers

- Landscape Architects

- Structural Engineers

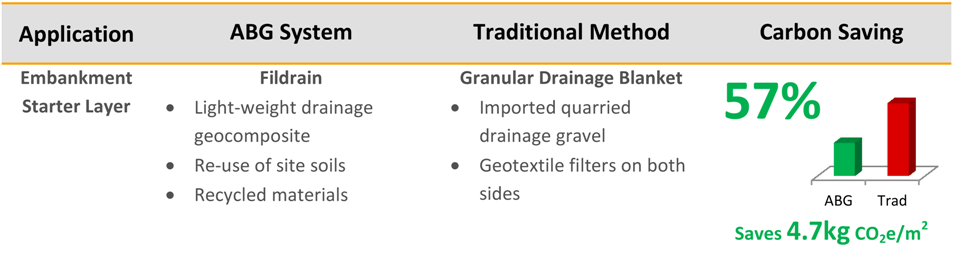

Earthworks and Embankment Starter Layers – Carbon Footprint Saving

The use of ABG’s Fildrain Drainage Geocomposite can save up to 57% on carbon footprint compared with traditional granular starter layer methods:

Click to read the full carbon footprint assessment