Truckcell® installation process

The following generic guidance must be read in conjunction with the specific project specification within the contract documents and the design notes below.

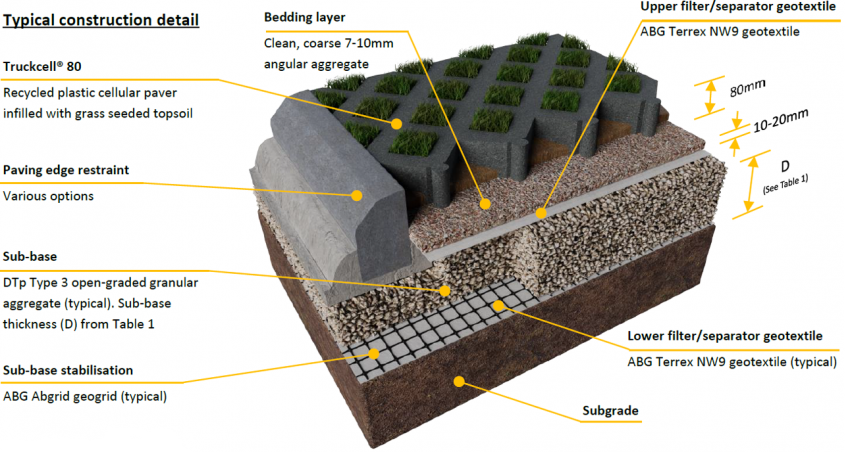

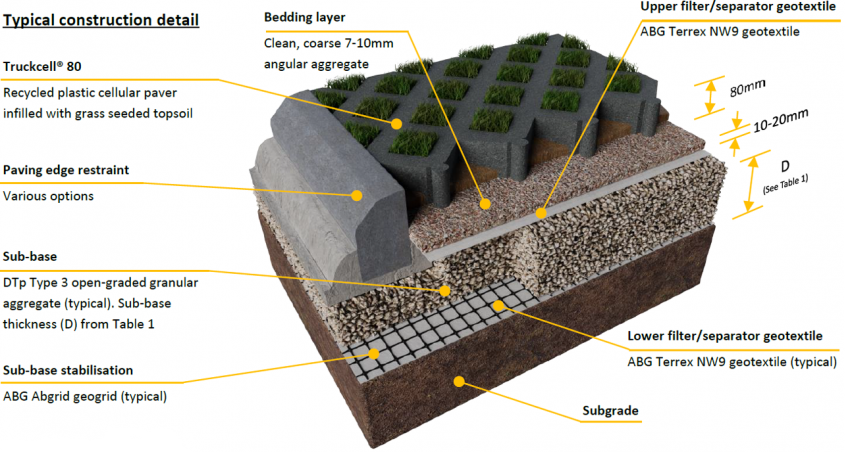

1. Install the specified lower ABG Terrex NW9 filter/separator geotextile and subbase stabilisation onto the prepared subgrade formation.

2. Install the specified subbase and edge restraints.

3. Install the upper filter/separator geotextile on top of the subbase.

4. Install the specified bedding layer to a uniform thickness.

5. Ensure an accurate right-angled Truckcell™ laying pattern by setting-out the site using string-lines. Check the lines regularly for accuracy. Start installing the Truckcell™ blocks. Wherever possible start laying from a right angled corner and progress across the site in rows. The blocks can be installed in a width or lengthwise orientation and cross-bonded if required or appropriate to fit the site. When installing the interlocking type blocks (80mm thick) ensure that the male/female connectors are fully located together. Use protective gloves to avoid abrasions.

6. Truckcell™ Pavers can be cut to fit around obstructions & curves using a hand or power saw. Wherever possible avoid using small cut-pieces less than one-third original size.

7. When installed, fill the paver cells loosely to the finished level (top of cells) with the specified cell infill. Remove excess soil from the surface of the pavers and do not overfill. A single pass with a light vibrating plate machine or roller may be used to firmly bed the pavers and settle the soil, but do not compact the soil. Do not vibro-roll. It is preferable that the soil is left just below the top of the cells to aid quality grass growth and reduce traffic abrasion. The surface may be trafficked by slow moving plant during the cell filling process, but care must be taken not to displace the open celled grids.

8. Apply the grass seed at the supplier’s recommended rates.

9. The surface may be trafficked immediately after the cells are filled. However, it is strongly advised that the grass is allowed to establish fully, then mown 2 or 3 times, prior to regular use.

10. A routine management and maintenance programme, to keep the surface in good condition and free of debris and weed growth, will help to sustain the porosity, quality and longevity of the system.

Notes

a. Advice on subgrade CBR% strengths, ground conditions, and construction over weak ground is available from ABG.

b. Alternative ABG stabilisation geosynthetics may be used in lieu of ABG Abgrid geogrid. These include ABG Gridtex Type 2 high strength woven geotextile or ABG Abweb geocells. If the subbase stabilisation is omitted, the total subbase layer thickness (‘D’ on Table 1) is typically increased by a minimum of 50%.

c. A permeable open-graded (reduced-fines) aggregate is recommended, such as DTp Type 3 low-fines roading aggregate, or BS 7533-13:2009 SuDS aggregate (4/20 or 4/40). However, where a conventional DTp Type 1 subbase is to be used, it is essential that a drainage system such as ABG Fildrain is incorporated. Specific advice is available from ABG.

d. Maximum subbase particle size should match minimum subbase thickness, but must not exceed 75mm diameter. For subbase thicknesses of around 100mm, a minimum 37.5mm particle size should be adopted to allow effective installation of the Abgrid.

e. Typical paving edge restraint solutions include: concrete, timber, railway sleepers, steel and heavy-duty plastic.

f. The subbase must be overlaid by a Terrex NW9 geotextile to provide separation, enhanced water treatment function and prevent migration of the bedding layer.

g. To provide a stable bedding layer for Truckcell, the bedding layer must not be sand.

h. The paver fill material should suitable for healthy grass growth. Amenity grass seed mixture should contain hard wearing, low fertility and/or drought tolerant species with a low percentage of clover content if acceptable.

i. The maximum advised gradient for vehicular trafficked applications is 8% (1:12) 5°.

j. When designed in accordance with the recommendations, Sudspave complies with BS8300:2009 : “Design of buildings and their approaches to meet the needs of disabled peopled” – Code of Practice (ISBN 9780 580 57419) & Building Regulations Document ‘M’ Section 6.

k. All stated dimensions & weights are nominal and in accordance with manufacturing +/- tolerances. Truckcell manufacturing tolerance +/-1.5%.

l. The recommendations in this document are only suitable for use with ABG products.

Table 1: Truckcell® typical DTp Type 3 subbase thickness (D) requirements – refer to specific construction drawing

| Vehicle Load & Frequency |

CBR (%) strength of subgrade soil (Table 2) |

(D) DTp sub-base thickness (D, mm) |

Abgrid Geogrid |

| Light vehicles with emergency HGV access |

6+ |

100 |

20/20 |

|

=4-6 |

100 |

20/20 |

|

=2-4 |

120 |

30/30 |

|

=1-2 |

220 |

30/30 |

| Light vehicles with one HGV per week |

6+ |

125 |

20/20 |

|

=4-6 |

150 |

20/20 |

|

=2-4 |

200 |

30/30 |

|

=1-2 |

325 |

30/30 |

| Light vehicles with 10 HGV’s per week |

6+ |

165 |

20/20 |

|

=4-6 |

200 |

20/20 |

|

=2-4 |

275 |

30/30 |

|

=1-2 |

425 |

30/30 |

| Regular HGV access |

6+ |

200 |

20/20 |

|

=4-6 |

250 |

20/20 |

|

=2-4 |

350 |

30/30 |

|

=1-2 |

500 |

30/30 |

Table 2: Field guidance for estimating subgrade shear strengths

| CBR (%) |

DCP Result 1 (Sandy Soils) |

HSV Result 1 (Clayey Soils) |

Tactile (Clayey Soils) |

Visual (Clayey or Sand Soils) |

| 1 |

<1 |

<30 kPa |

Easily indented by fingers |

Adult standing will sink >30mm |

| 1-2 |

<1 |

30-60 kPa |

Indented by strong finger/thumb pressure |

Adult standing sinks 10-30mm |

| 2-4 |

1-2 |

60-120 kPa |

Cannot be indented by thumb pressure |

Utility truck ruts 10-25mm |

| 5-7 |

2-3 |

120-200 kPa |

Can be indented by thumb pressure |

Loaded construction vehicle ruts by 25mm |

| >8 |

>3 |

>200 kPa |

Difficult to indent by thumb nail |

Loaded construction vehicle ruts by <10mm |