Project Description

The Balsa de El Golfo reservoir basin is located on the small island of El Hierro which is the most westerly of the Canary Islands. With a capacity of 120,000 cubic metres, the basin provides irrigation for 200 hectares of tropical pineapple, banana and subtropical fruit crops on which the El Hierro economy depends.

Since it was first built in 1993 it had not undergone any renovations and the original 30 year old geomembrane liner was now out of the warranty period. The slopes therefore required re-waterproofing as part of €3.5 million of upgrade works awarded to the Tragsa Group.

The Challenge

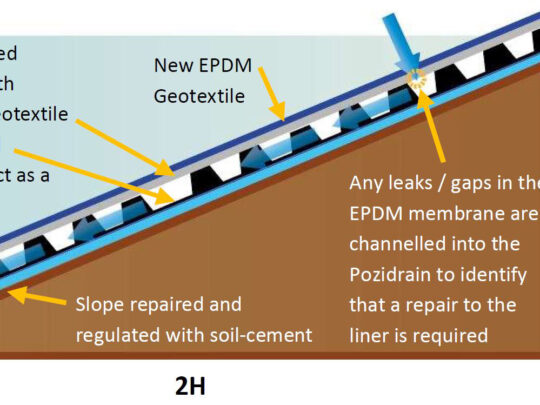

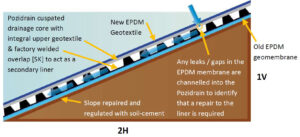

With a maximum height of 14 metres of water, the head acting on the liner is substantial. Most EPDM (ethylene propylene diene monomer) geomembranes are subject to microscopic holes / gaps in the installation which may cause leaks as a result of the hydrostatic pressure. A secondary drainage layer is therefore typically specified to detect and channel any seepage water, often with provision to alleviate ground water pressure uplift and floatation of the liner when the basin is empty. A stone drainage layer alternative would be difficult (and carbon intensive) to transport and construct to the correct depth on the steep sided slopes of the reservoir. They are also prone to having sharp edges that pose a risk of puncturing the liner. In the event of any water penetrating through the primary liner, it is also harder to isolate and control the leak in a stone drainage layer.

The Solution

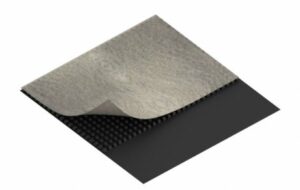

ABG’s Pozidrain geocomposite was specified for the leak detection and drainage layer and to alleviate the risk from pore water pressure causing wider spread damage in the event of a tear. The 6mm deep cuspated drainage core provides a controlled in-plane flow rate that is equivalent to an approximately 150mm thick layer of stone, whilst the integral geotextile bonded to the upper surface of the core serves to filter and prevent any sediment from blocking the drain.

Large roll sizes of 5.5m wide x 96m length provided rapid coverage to line the basin. Also integral to the success of the installation was the specification of the 5.5m wide Pozidrain with a factory welded selvedge core. Adjoining rolls were then overlapped and sealed using an extrusion welder to heat bond the geotextile and HDPE core layers together. Collector drains at the bottom of the basin enable any water channelling through the cuspated core to be detected and the source of any leaks identified.

Pozidrain installed to line the base of the reservoir with cuspates and upper geotextile facing upwards to channel and detect any leakages in the primary EPDM waterproofing. The underside of the core is impermeable and joined with a selvedge overlap.

Producers in the Valle del Golfo are now able to use the irrigation water from the renovated reservoir, with the installation of a new fabric roof to minimise evaporation, new lighting and the improvement of the inlet collector to follow.

The ABG Service

ABG assisted with the product specification, export and shipping of the Pozidrain rolls to the remote El Hierro island location.

![Pozidrain 6SK250/NW16[L80]](https://abg-geosynthetics.com/wp-content/uploads/Pozidrain_SKL_1.jpg)