Project Description

Botswana Power Corporation needed to rehabilitate an unlined ash dam in order to prevent potentially harmful environmental contamination caused by exposure to rainwater and wind. Water entering the ash could result in potentially harmful leachate entering the groundwater due to the lack of basal lining and erosion would also be an environmental hazard.

The Challenge

A standard liner and drainage solution had been considered but was found to be prohibitively expensive. A priority was to find an affordable low cost solution for lining and draining the cap whilst providing an engineered containment of sufficient integrity. The extensive and shallow 3% cross-fall plateau required a high capacity drainage solution to prevent ponding from the 400mm annual rainfall, mainly during heavy afternoon thunderstorms. Steep 1 in 3 side slopes required stability assurances for the capping layers. In addition, approaching seasonal rains conferred urgency on the project.

The Solution

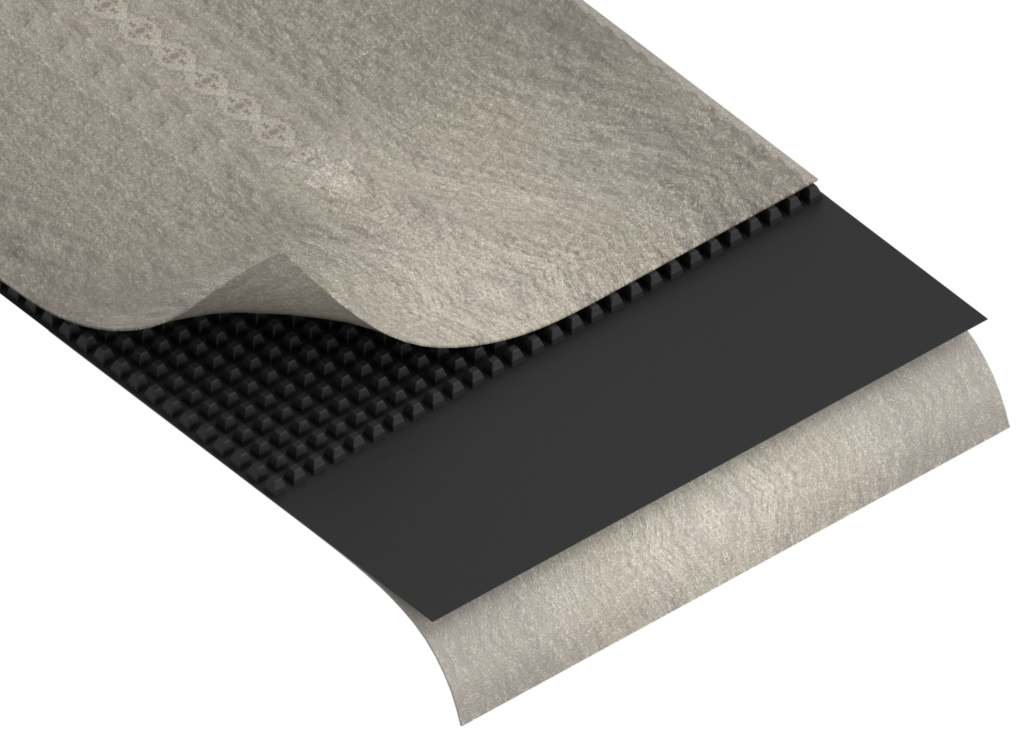

Initially the impermeable Pozidrain drainage geocomposite rolls were to be overlapped such that the gradient would prohibit entry of sub-surface water to the containment, however, due to the largely rectangular geometry ABG’s “J” version Pozidrain geocomposite was used. This had 100mm flat edges to both edges of the rolls, enabling sufficiently strong and tight joints to be made and sealed by hot air welding.

Site specific cover soil permeability tests were made and anticipated water volumes and flow capacities calculated. By comparison with ABG’s flow vs gradient tables Pozidrain 7SK250D/NW8[N2,J100] drainage geocomposite was subsequently chosen for its long term drainage capacity.

Slope stability calculations proved Pozidrain gesoynthetic to have sufficient shear strength at both interfaces due to the high friction textile on both sides of the drainage core.

ABG Pozidrain Flat selvedge on each edge allows welding and geotextile flap protects joint

The ABG Service

ABG contributed fully to the value engineering of the project by eliminating the need for separate liner and drainage layers, also reducing installation costs, whilst still enabling confidence in the long-term function and performance of the product. Additional savings were facilitated by the use of two different roll widths, both with 100mm flat edges, which maximised container capacity and reduced the number of containers.

ABG’s extensive experience in landfill meant that both consultants and contractors were fully supported from design to installation with test data, calculations, bespoke manufacture, timely delivery and installation advice.

Contact ABG today to discuss your dam or capping project specific requirements and discover how ABG past experience and innovative products can help.