Project Description

Potential sites around Belfast, Northern Ireland that would be suitable for an MSW landfill are in short supply. Alpha Resource Management appointed RPS to investigate the feasibility of using a former quarry at Mullaghglass as a landfill site. RPS undertook outline design and produced an Environmental Impact Assessment prior to submitting the project for planning permission. Following receipt of planning permission, RPS submitted a PPC permit application and undertook detailed design for the entire site.

The Challenge

The new cell was designed to comply with the EU Landfill Directive which requires a competent lining system that would contain the waste and prevent leachate escape into the ground. A conventional composite lining system was detailed on the base of the cell, comprising a 500mm layer of compacted clay overlaid with an HDPE geomembrane. A protection geotextile would be installed underneath the 500mm of 20/40 crushed stone leachate collection layer.

The walls of the quarry were almost vertical and to grade these into a clay slope suitable for lining would drastically reduce the void space of the landfill. The rock face of the quarry was too rough and steep to omit the clay and place a geomembrane however. In addition, it would be difficult to place a crushed stone leachate drainage layer up the vertical face. Conversely, if a geosynthetic drainage layer was used, it would be exposed to UV from sunlight for up to 12 months which would be beyond the usual limit for geosynthetics.

The Solution

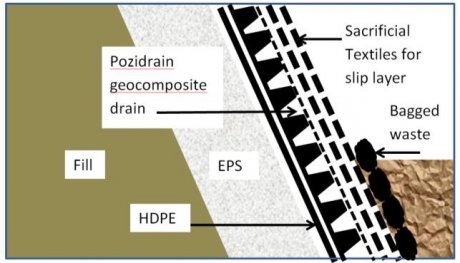

RPS used shaped blocks of expanded polystyrene on the quarry wall for a permanent facing. Together with compacted fill, a smooth and stable 70o slope was created. Berms were formed at each 10m rise on which the HDPE geomembrane and the Pozidrain geocomposite drain were anchored.

The specification for the geocomposite required creep at 500kPa pressure to be limited to less than 25% in 114 years according to the ASTM D7361 Stepped Isothermal Method. Pozidrain 7S500D/NW20XUV/NW8 met the creep requirements and had a proven in-plane flow equivalent to 500mm depth of 20/40 crushed stone. The NW20XUV geotextile is suitable for 12 months exposure in the UK and a further two sacrificial layers of geotextile were placed over the Pozidrain to provide a slip surface and 2 years additional protection.

Pozidrain drainage geocomposite was used as a replacement to crushed stone, resulting in reduced installation time and cost. Void space consumed for drainage provision was also lower, giving more volume for waste and thereby increasing revenue.

Pozidrain 7S500D/NW20XUV/NW8 geocomposite

The ABG Service

ABG performed in-plane flow tests, SIM creep tests and UV tests to demonstrate that use of a geocomposite was a feasible and reliable method of steep side wall basal drainage on this difficult site.

Contact ABG today to discuss your landfill drainage project specific requirements and discover how ABG past experience and innovative products can help.