Project Description

The Roundhill landfill site, located within the Buffalo City Metropolitan Municipality in the Eastern Cape of South Africa, has been in operation since February 2006 and currently accepts around 600 tonnes of general waste per day. As the volumes of waste grew over the years, so did the operational challenges and the site fell into a position of non-compliance as a result; with areas of uncompacted and uncovered waste accumulating due to shortages of cover material, and unsafe steep slopes being created owing to the limited amount of lined airspace available.

The Challenge

Damage to the leachate and stormwater management systems, coupled with the unlined waste areas, led to uncontrolled flows. This was creating a negative environmental impact on local groundwater sources and so specialist landfill consultants were appointed by the municipality to compile a turnaround strategy for the site.

The Solution

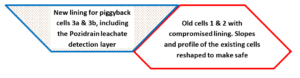

The slopes and profile of the existing cells were reshaped and rehabilitated to make them safe again, alongside repairs and upgrades to the stormwater, leachate management and cell liner systems. Critical to reinstating environmental compliance was the creation of a new cell so that areas of unlined waste and new incoming refuse could be safely contained. The new cell required a leachate detection layer to demonstrate that the lining is draining adequately and containing the deposited landfill as intended. The new cell areas 3a and 3b piggyback laterally onto the existing cells 1 and 2 (Fig. 1). For this particular application the Pozidrain 7SK250/NW8 [L, UV AO] layer was specified in order to prevent and detect any leachate from the new waste soaking through to the compromised original cell and causing further contamination.

Pozidrain SK[L] Fig. 1 Piggyback cell design

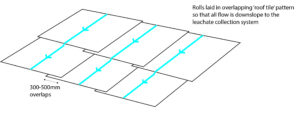

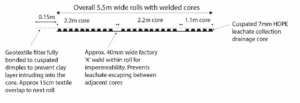

The Pozidrain 7SK[L] product was specified since it features a welded cuspated core to prevent leachate escape (Fig. 2). The 5.5m wide continuous sheet is made up of 3 cores (2.2m, 2.2m & 1.1m) factory welded together (as denoted by the ‘K’ in the product name). The large roll width provides fast coverage, and the adjoining rolls are overlapped in a roof-tile pattern down the cell slopes so that leachate does not run through the overlaps, with minimal sealing of edges required as a result (Fig. 3).

Fig. 3 Rolls overlapped downslope to Fig. 2 Pozidrain 7SK250/NW8[L] configuration

prevent leachate ingress

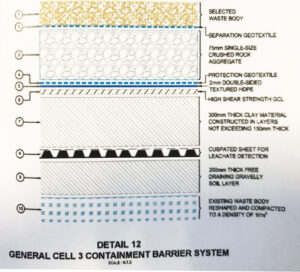

The complete landfill lining design consists of 10 layers (Fig. 4); including a 200mm thick gravelly soil regulating layer above the existing waste in cells 1 and 2, the ABG Pozidrain leachate drainage and detection layer (shown in layer 8) installed below a 300mm layer of compacted clay and GCL, an HDPE liner and protection geotextile and a crushed stone drainage layer and separation geotextile.

Fig. 4 Lining, leachate management and drainage layers for existing cell remediation and new piggyback cells

The Pozidrain 7SK[L] HDPE cuspated core is laid with dimples facing upwards to collect and channel any leachate and includes a non-woven geotextile bonded to the upperside to stop intrusion of the clay layer into the drainage channels. In the event of any damage to the HDPE membrane or clay capping layer, the Pozidrain system channels the leachate to a detection sump and enables the Roundhill site engineers to identify and repair leaks in the liner as required.

The ABG Service

Assistance and technical calculations for slope stability and long-term flow expectations based on the site specific design pressures.