Project Description

“Nestled in the picturesque and historic Holme Valley, a stone’s throw away from the cobbled streets of Holmfirth and flanked between ancient woodland and the gentle ebb and flow of the river Holme…. lies Devour”…the opening description for the redevelopment of a historic abandoned mill in the Thongsbridge area of Holmfirth as a new restaurant and cookery school. The restaurant expects a large number of customers from the area and further afield. A large car park was planned, with landscaping along the river blending into the beautiful surroundings.

The Challenge

Part of the planning consent for the project was to provide a SuDS compliant attenuation and a regulated flow outlet from the site into the River Holme. The client also required the car park to look as natural as possible. Initially a series of buried SuDS tanks were specified to take the rainfall run-off from the site which would require additional excavation and backfill. The water table remained high, even at some distance from the river. In addition a root barrier geomembrane was required to prevent growth up through the car park. This meant no natural infiltration of rainwater was possible. Special ground stabilisation proposed by ABG was used to prepare the subbase (See ABG Stabilisation Devour Mill Case Study).

The site has a narrow entrance which opens out to the car park and requires delivery lorries to enter and turn around safely before exiting. This would potentially put pressure on the durability of the surface.

The Solution

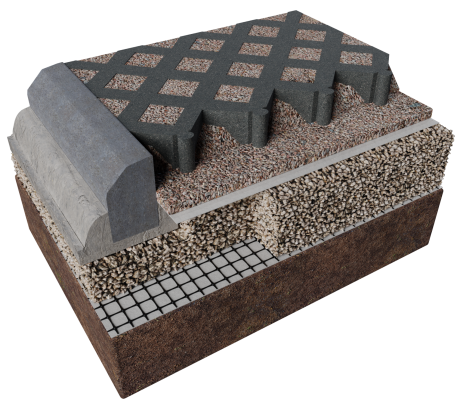

ABG offered a re-engineered solution, showing that a porous Type 3 subbase attenuation stone over the whole car park would provide the storage volume needed to handle the predicted stormwater and that discharge could be restricted to consent levels. This removed the need for expensive buried tanks with the associated added excavation and need to remove contaminated soil. The majority of the running surface for cars was covered with Sudspave interlocking pavers, coloured especially to match the selected infill gravel to create a natural look. The delivery goods vehicle turning area used the heavy duty Truckcell 80 paver filled with the same gravel. Once the Type 3 was levelled, both pavers were bedded on a regulating layer of gravel and filled.

ABG Sudspave 40 Permeable pavers with gravel fill

ABG Truckcell 80 recycled plastic porous paving grids

The ABG Service

ABG offered re-engineering design support and advice, including technical calculations and site visits. Bespoke coloured pavers were also provided.

Contact ABG today to discuss your permeable paving project specific requirements and discover how ABG’s past experience and innovative products can help.