Traditional back of wall drainage (as per SHW clause 513) consists of either hollow concrete blocks filled with single sized stone, or no fines concrete built above a perforated pipe.

This allows any water that may build up behind a retaining wall or a bridge abutment to escape and release the hydrostatic pressure behind the earth retaining structure. On the A14 other proven methods were sought that can offer the same performance, at the same time as offering further benefits in comparison to traditional methods.

After being accepted through the Materials Approvement Request process, Deckdrain was specified on the BN06 East Coast Mainline bridge as an environmentally friendly alternative to traditional structural drainage techniques that utilise aggregates.

Since Deckdrain is installed by hand there is a zero requirement for plant during the backfilling process. By not involving any plant to install, Deckdrain boasts zero emissions produced during installation in comparison to traditional back of wall drainage materials.

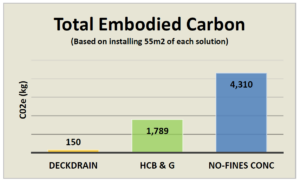

The exact amounts of embodied carbon for the various solutions are as follows:

Based on these figures there is a huge reduction in embodied carbon across the bridge structures and the BN06 East Coast Mainline bridge. The embodied carbon (C02e) realised through installing Deckdrain amounted to 4.17T which compares to 49.7T if hollow blocks had been used and 119.8T if no fines concrete had been used.