Project Description

Grassholme reservoir supplies water for Teesdale and Teeside, and has been undergoing a 3-year maintenance and improvement plan to ensure future resilience – not just for the reservoir, but also for the surrounding area. These works include the rebuilding of two spillways, provision of a new anglers’ beach and the temporary diversion of a stream whilst reprofiling of an embankment takes place.

The Challenge

The face of the dam crest and the spillway required improvement to better cope in the event of overtopping. Water will flow down the spillway face at speeds over 4m/s and even a well-established grass sward would only withstand these flow speeds for a short period without reinforcement.

The Solution

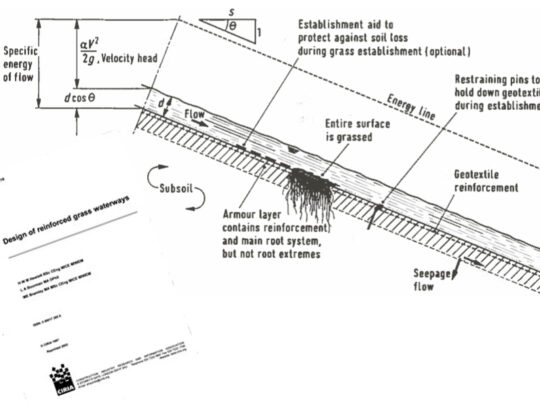

To improve resilience and extend the period that the spillway can withstand an overtopping event, ABG’s Erosamat 3/20Z 500M erosion control geosynthetic was chosen as a permanent Turf Reinforcement Mat (TRM) that meets the design requirements of CIRIA Report 116 and to protect against die-back of the grass.

ABG’s Erosamat 3/20Z 500M was chosen for two reasons: firstly, it provides the long-term support of a TRM as per CIRIA 116 “Design of Reinforced Grass Waterways”, and, secondly, because it incorporates a geogrid mesh to provide additional strength from wave action.

The face of the dam is roughly 45°, so access was not very easy (especially during the Winter months) and Health & Safety was of prime concern. Stripping the vegetation was challenging, and a remotely operated flail mower was used to reduce the risk of operatives slipping down the bank. Unlike traditional Erosamat installations, both the top and toe anchors were to be undertaken in a slightly different manner. The Erosamat was anchored at the top under the newly installed kerb for the access road along the crest of the dam, whilst the toe trench was a 700mm slit trench cut using a GeoRipper. This reduced the manpower needed on the face of the dam and, again, reduced risk.

Once in place, the Erosamat was hydroseeded. Now complete on site, vegetation has started to develop through the Erosamat, and will soon completely cover it, allowing the farmer to let his sheep graze on the embankment once more.

The ABG Service

ABG’s engineering department assisted consulting engineers Stantec by reviewing and verifying the site design drawings and installation details.