Project Description

The Staffordshire Alliance consortia (Atkins Rail, Laing O’Rourke, Network Rail and Volker Rail) carried out extensive improvements to the line between Crewe and Stafford to remove a major bottleneck on the West Coast Mainline. By allowing trains travelling to Manchester from the South and West Midlands to travel over, rather than across the existing tracks, the line now accommodates two extra trains per hour. The scheme was a £250m investment and forms part of Network Rail’s £40bn Railway Upgrade Plan. It won multiple awards for Innovation, Collaborative Working, Best Major Project and others from various industry bodies.

The Challenge

This highly complex project included the construction of 11 new railway bridge structures and 650,000 tonnes of bulk earthworks. The construction programme and the possession times allowed on the project were critical to its success. The scheme employed a dedicated Innovation Manager to aid Engineers and Contractors in finding ways to improve construction by identifying faster methods, cost savings, reducing vehicle movements and removing the need for material import. The traditional granular drainage for the new buried structures was one of the areas where innovation would contribute to a significant improvement.

The Solution

Laing O’Rourke proposed the use of ABG’s Deckdrain geocomposite to provide an effective, time saving drainage solution for the rail bridge structures in place of the granular fill originally specified. ABG Deckdrain is a BBA HAPAS approved wall drainage geocomposite, and manufactured in the UK.

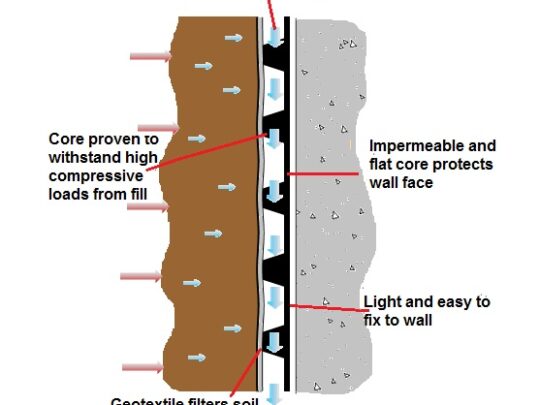

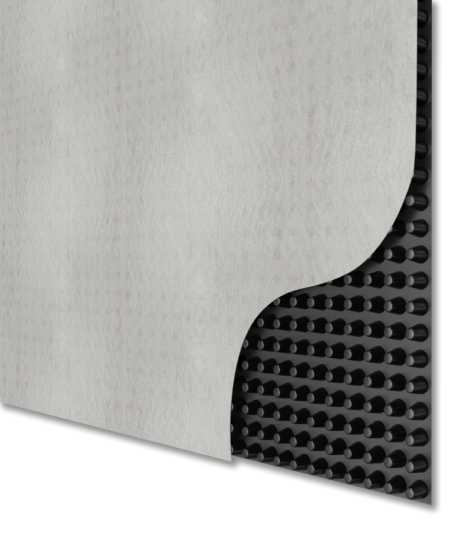

Deckdrain drainage geocomposite comprises a high performance cuspated drainage core which optimises waterflow. It provides water flows many times the capacity of typical drainage stone, and on this scheme saved approximately 1,000t of granular material import. The flat backed impermeable core protects the concrete waterproofing from installation damage, while the filter geotextile is compatible with site won soils.

The rolls of Deckdrain geocomposite are easy to handle and attach to the wall. It is simply cut, shaped and sealed around any protrusions and is easy to handle in tight working conditions such as behind abutment walls.

ABG Deckdrain geocomposite for vertical wall drainage

The ABG Service

ABG provided detailed design calculations and advice, drawings and installation advice.

Contact ABG today to discuss your project specific requirements and discover how ABG past experience and innovative products can help.