In 2014, heavy storms along England’s southern coast destroyed a section of the iconic Dawlish sea wall (originally constructed by Brunel in 1840) leaving only a swing bridge of rails behind. This resulted in an eight week closure of the South Devon Railway line, with the whole South West peninsula totally cut off from the rest of the network. Once the emergency works were completed to temporarily restore the line, Network Rail put a plan in place to improve the railway’s future resilience and further protect it from rising sea levels and extreme weather events. In early 2019, the Department for Transport committed funding for Phase 2 of the wall, a 400m section between the Grade II listed station building and the Coastguard breakwater.

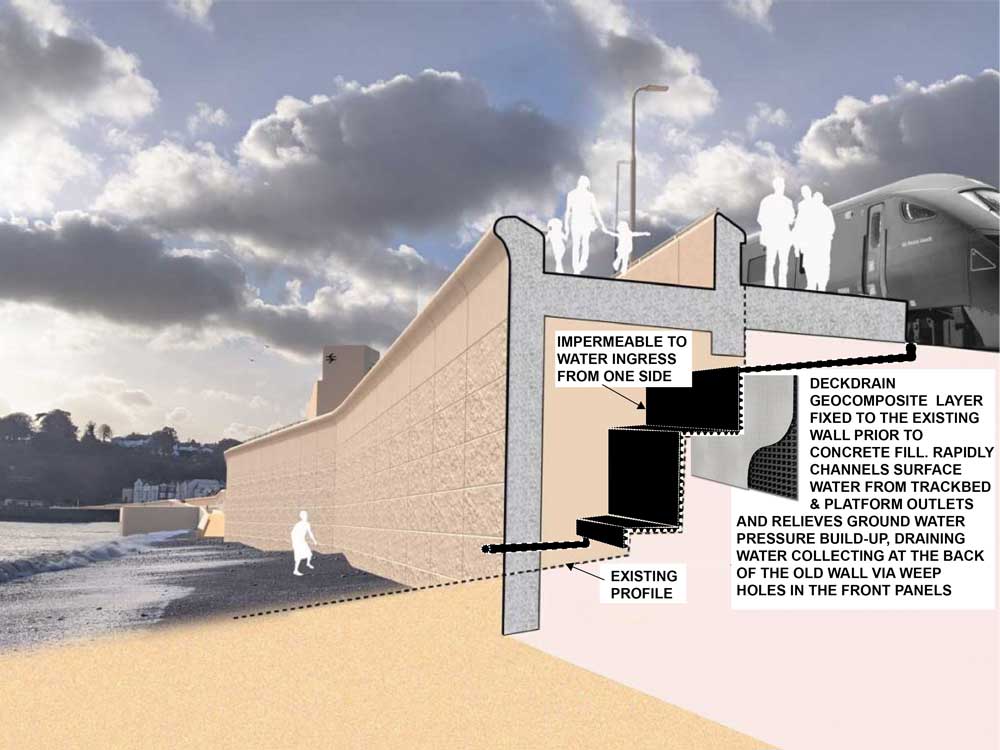

BAM Nuttall was awarded the £27.8M contract which includes the installation of 286 circular hollow section (CHS) piles into sandstone breccia rock along the coastline. The 762mm diameter CHS piles range from 12m to 16m long and are installed to support 150 x 14 tonne precast facing panels and to retain a series of in-situ concrete pours between the piles and the existing sea wall for the new promenade structure. An easy to install solution was needed to channel away rainwater and to relieve ground water pressure build-up from the back of the new structure.

To save installation time and space ahead of pouring the in-situ concrete structure to the back of the CHS pile wall, ABG’s 7mm thick Deckdrain 700S/ST170 drainage geocomposite was specified. This provided a thin, light-weight and quick to install alternative whilst working around the local tide tables, avoiding the transportation and time involved with using heavy crushed stone or hollow concrete block drainage methods. The cuspated drainage core provides high-flow drainage capacity over a large surface area to rapidly channel surface water away from the track-bed and platform outlets. The geocomposite also prevents the fluctuating ground water pressure from building up behind the wall, with water released via weep hole outlets at the front of the new concrete panels (positioned to prevent surcharge).

To find out more about the structural drainage design implemented on behalf of Network Rail for the new section of sea wall, the full case study can be viewed here.