TODDBROOK DAM Spillway Damage

Earth embankment dams are a common feature of the British landscape, so much so that they largely go unnoticed. That is until one almost collapses.

Many of these dams were constructed over 100 years ago, at a time when it was necessary to store reserves of water for canals, as well as for public water supply.

Today, such dams, of which there are approx. 3000 in Britain, are maintained and provide very important recreational amenity. Every reservoir over 25,000 cubic metres must comply with the Reservoirs Act 1975 (England &Wales, plus Scotland) and have annual inspections by a supervising and inspecting civil engineer.

The climate change in Britain means that dams are assessed to ever-more stringent conditions. Storms that at one time might have occurred one in 100 years, now occur more like every 10 years. The storm that hit Whaley Bridge in August 2019 had a probability of one in 5000 years. Such severe rainfall falling on the catchment area of the already full Toddbrook reservoir caused water to cascade over the emergency spillway.

This concrete spillway, located on a section of the dam face, was subjected to a continuous plume of fast flowing water.

A situation that the spillway should have coped with, but it did not. Why?

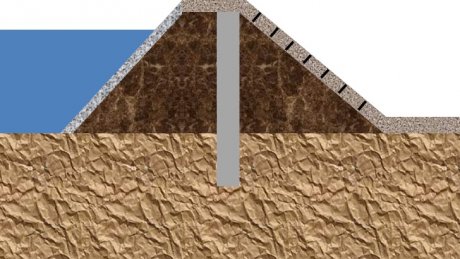

Fast flowing water is no different from fast flowing air, and just like an aircraft wing (that can lift a 300 tonne aircraft), the high speed water creates pressure reduction (suction) that can lift soil or concrete. If the joints between the concrete slabs that form the spillway were not properly sealed, the soil below would be “sucked out” by the fast flowing water, until the slabs collapsed.

We do not know yet what actually happened, but fortunately the damage was confined to the earth fill and the all-important clay core of the dam remained intact. Temporary support is now in place, and the water level in the dam reduced.

A disaster has been averted, and there will be a new spillway constructed.

Similarly, a new spillway was constructed for a dam in Meltham in 2014. To avoid risk to the dam, the new spillway was constructed away to the side of the dam itself. Formed from reinforced concrete, the designers contacted ABG to provide a geocomposite drainage layer below the concrete.

Deckdrain geocomposite shown below is a thin HDPE cuspated core bonded to a geotextile filter, and it provides a drainage layer below the concrete slab. Any seeping water can flow safely through the Deckdrain without causing pressure on the concrete slab. The geotextile provides a filter to allow water through but prevent soil intrusion.

ABG manufactures a whole range of geocomposite drainage products and is renowned for a high level of technical expertise, which can be demonstrated by their numerous case studies.

Drainage Geocomposite

Diagram illustrates how water can flow through the geotextile and into the core of the geocomposite before flowing into the drainage system.

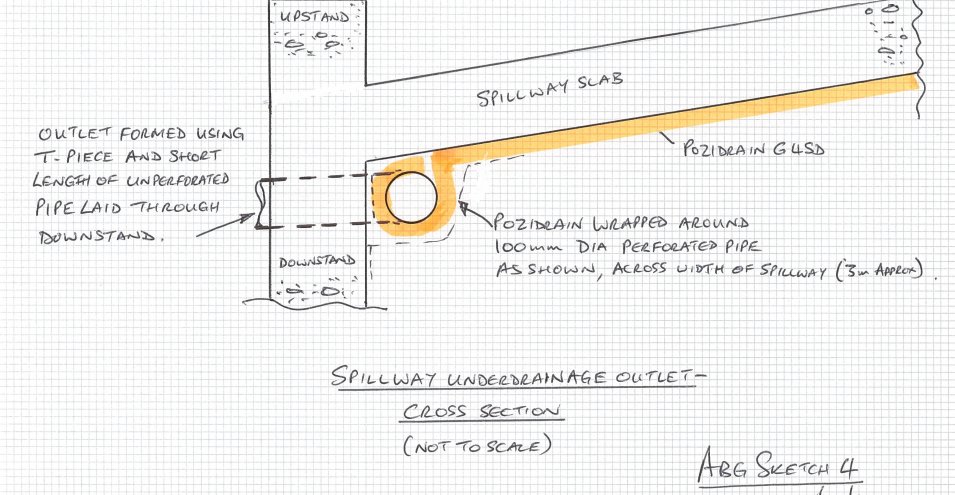

Spillway Underdrainage Outlet – Cross Section