ABG Deckdrain is a BBA HAPAS approved, UK manufactured drainage geocomposite, which provides factory consistent drainage performance, in both vertical and horizontal drainage applications. Drainage geocomposites can be an easily installed alternative to granular drains, meaning more site won spoil can be re-used.

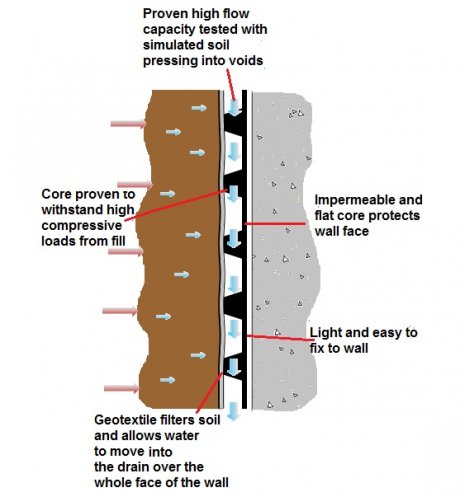

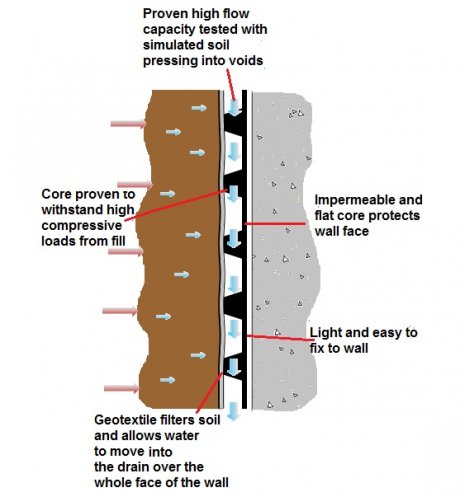

Deckdrain drainage geocomposite provides structural drainage that is up to 50 times more effective than drainage stone at a fraction of the material and labour cost. The geocomposite’s high-performance cuspated drainage core (thermally bonded to geotextile filter fabric) acts to maintain a free-flowing drainage void. Deckdrain is a light-weight, yet robust drainage layer which also offers protection to the waterproofing for the lifetime of the structure.

Deckdrain is simple to install to bridge abutments, buried concrete structures, retaining walls, culverts and cut and cover tunnels.

When compared to traditional permeable Type A filter gravel, the same volume of drainage can be achieved with a significantly thinner layer. That means Deckdrain provides cost effective groundwater management for underground structures, and has uses in highway tunnels where reducing the volume of dig out and import has huge financial benefits.

In certain applications, concrete can be cast directly into the back of Deckdrain making it ideal for sprayed concrete walls.

Using Deckdrain geocomposite can reduce the amount of excavation required on site and enables excavated material to be re-used as backfill. That means vastly reduced vehicle movements to and from site, representing up to a 95% reduction on carbon emissions and improved safety when compared to transporting traditional methods.

ABG provide full technical support for the design of structural drainage within the highways market.

Deckdrain geocomposite used for drainage on highway structures

Bridge abutment drainage system & geocomposite against a buried structural abutment

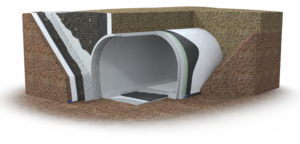

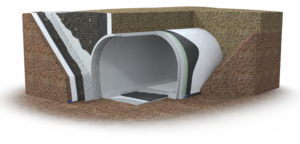

Tunnel Drainage – Cut & Cover

ABG Deckdrain is a high performance geocomposite drainage system, providing an effective and environmentally friendly alternative to traditional granular structural drainage for tunnels. ABG Deckdrain has a high flow capacity and provides added protection to the external walls of the tunnel.

The HDPE cuspated core of the geocomposite provides a free flowing drainage void allowing water to flow in all directions, unlike linear or pipe systems. The cuspates are designed to support the stiffened filtration geotextile which is thermally bonded to the core. This ensures that the geotextile does not deform into the drainage void under the pressure of the backfill material. More information about flow testing.

ABG Deckdrain is durable and sufficiently robust to resist the mechanical stresses imposed during installation and then on throughout its design life. The use of ABG Deckdrain eliminates the need for further protection of the waterproofing system. Deckdrain has been creep tested at compressive loads of up to 1,000 kPa to give a design life of 120 years.

For cut and cover tunnels, Deckdrain can be used for the external drainage layer

For the internal and invert tunnel drainage our Cavidrain geocomposites should be considered.

ABG are a market leader in the development, manufacture and technical support of high performance geosynthetics with applications across the whole spectrum of highways infrastructure. Contact our team with your project requirements.

ABG Deckdrain is durable and sufficiently robust to resist the mechanical stresses imposed during installation and then on throughout its design life. The use of ABG Deckdrain eliminates the need for further protection of the waterproofing system. Deckdrain has been creep tested at compressive loads of up to 1,000 kPa to give a design life of 120 years.

For the internal and invert tunnel drainage our Cavidrain geocomposites should be considered.