Following the Nichols report “Review of Highways Agency Major Road Program” the Highways Agency developed their managing down costs toolkit to identify cost saving opportunities at various stages of scheme development. Highways England continue to promote these ideas, many of which rely on the types of geosynthetics supplied by ABG.

Value Engineering – Highways schemes offer many opportunities for true value engineering

Installation & Environmental Benefits – Using geosynthetics in Highway construction reduces material movements, and provides multiple environmental and sustainability benefits

Reducing the risk – Using geocomposite drainage in place of granular drainage options means factory consistent performance

The Specification for Highway Works (SHW) has been developed by the Department for Transport over many years, and forms the basis for many of the major civil engineering works undertaken in the UK. The Nichols report identified that opportunities to adopt new ideas and technology which offer costs savings were not being taken full adavantage of, and to address this the Highways Agency developed the Managing Down Costs (MDC) Toolkit.

The toolkit comprises a number of ideas that may help bring down the cost of construction, and are not exclusive to highway schemes. ABG geosynthetic systems can be used in a number of ways to realise these ideas, and our technical expertise means we can you help to get the most out of them to meet sustainability objectives as well as reducing the cost and installation time when compared to traditional methods.

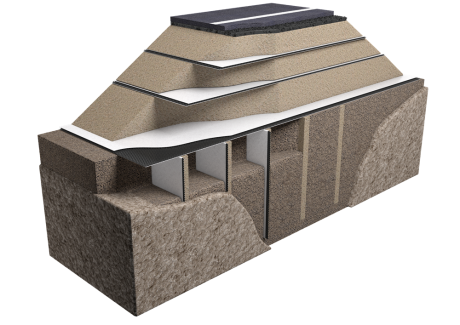

Embankments, Starter Layers and Settlement Control

Where large scale earthworks are involved, for example when building embankments, settlement control and consolidation can be expensive. Consideration must be given to the time taken for consolidation before the next phase of works can commence.The toolkit contains a number of ideas relating to these areas of construction.

Replacing a granular starter layer with a geocomposite drainage layer such as Fildrain 7DD (idea 240) means a huge reduction in the virgin material imported to a site. Fildrain is significantly faster to install, and our M8 case study show this in use on a major road.

Fildrain can also make it possible to utilise site won and recycled materials (idea 46h) that would otherwise be classified as unsuitable. It can also allow use of over wet fill in construction by accelerating the consolidation period. Our Ashton Moss case study shows this in action near Manchester.

High strength geotextiles can be used in the construction of embankments (idea 250) to allow steeper and higher construction.

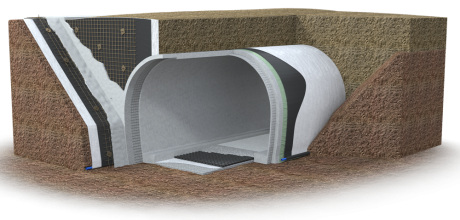

Structures

Highway structures need to be properly protected with drainage and waterproofing to prevent failure or shortened design life.

Off-site construction and pre-cast units (idea 223) save a lot of time, and can minimise the effects of new developments on watercourses and biodiversity. ABG Deckdrain is a BBA approved structural drainage system which removes the need for granular or porous block drainage. This reduces the environmental impact, and can be pre-installed before the structure reaches its final position. The Rosper Road Rail Bridge case study shows Deckdrain being used to reduce risk on a tight time scale bridge slide.

Geogrids can be used to build reinforced earth structures (idea 27) to form earthworks and reinforced structures as illustrated by our A50 case study. Bridge abutments can be built in this way (idea 90), as can embedded retaining walls (idea 218). Where a piled wall solution is required ABG Deckdrain and Piledrain offer a simple and effective drainage solution.

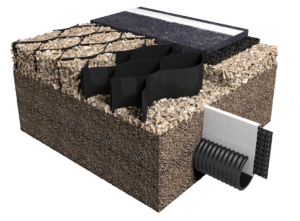

Highway Edge

There are a number of techniques that can be used at the edge of the carriageway. Filter drains are considered a very cost effective solution (idea 23a) to manage ground water flows from cuttings, or where roads have long and flat longitudinal gradients, but they can introduce the risk of stone scatter.

Concertinaweb provides stability to the surface layer of the filter drain which controls stone scatter, and provides a safe surface in the event that a vehicle runs off the main carriageway. Alternatively reinforced turf (idea 213) such as ABGs Advanced Turf System can provide a trafficable grass finish. Our York University case study shows this principle used to create emergency access routes.

Highway Edge drains are traditionally a simple stone filled trench, but the SHW also allows use of geocomposites with the appropriate BBA HAPAS approval as a standard detail.

ABG Fildrain Types are BBA approved for Highways edge drainage and comply with SHW requirements. Our A1 Dishforth to Leeming case study and our A1 Leeming to Barton case study show these drains in use. This technique contributed to the scheme winning an Environmental Sustainability award.

Rather than relying on imported stone, Fildrain Types provide drainage, and have the added benefit of allowing re-use of site won fill to backfill the trenches (idea 46 and idea 23a), which also means a significant benefit for the Site Waste Management Plan (idea 247).