Project Description

Rosper road railway bridge is part of an improvement scheme to upgrade rail and road access to the Port of Immingham. The scheme will also improve safety by providing a new bypass. An investment of £88.4 million has been made to upgrade the A160 and the A180 nearby. Immingham handles more cargo than any other UK port and therefore it was essential the road network was upgraded to support growth and investment in the area.

The Challenge

The rail line over the A160 is a critical route for the supply of fuel to power stations across the north of England. Network Rail could only allow a very short possession time, which meant that the 4,000 tonne bridge had to be built next to its final position, and then slid into place over a period of less than three days during Christmas 2015.

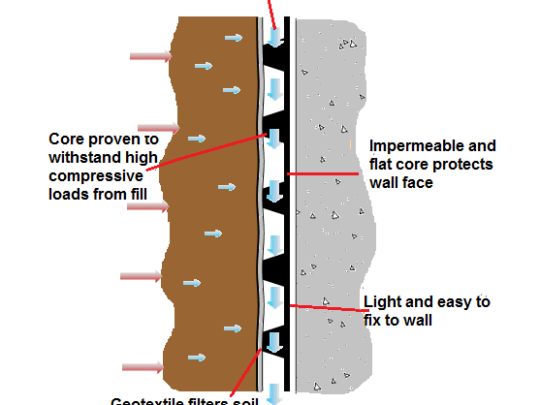

Due to the complexity of the works, the project team needed to find major time savings for operations during the possession. They identified that the specified granular structural drainage could be replaced by a system that could be installed on the bridge before the slide, and therefore simplify the placement of fill once in place. The drainage system needed to drain water rapidly from the structure to avoid causing a reduction of shear strength in the fill, which puts unnecessary pressure on the structure, while being robust enough to allow fill to be placed quickly after the slide. A long design life was also needed to avoid future maintenance.

The Solution

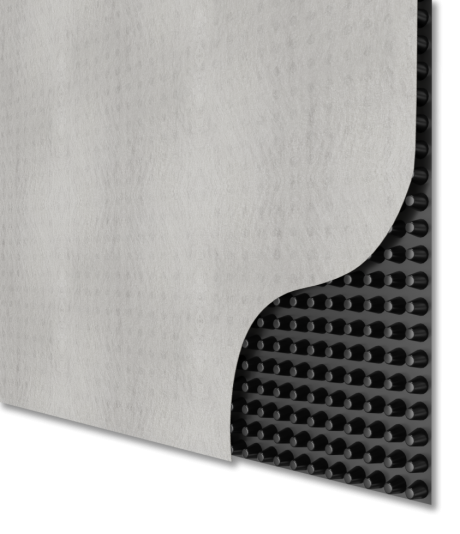

After considering a number of options, ABG’s Deckdrain geocomposite was selected as the best drainage option since it provided an easy to install, robust drainage solution for the railway bridge structure.

Deckdrain offers many times the in-plane flow capacity of a typical granular drainage layer and offers the advantage of a flat-backed impermeable core to protect the concrete face from installation damage and further waterproofing the structure. The ease of handling the rolls helped to minimise the manpower needed, and Deckdrain is easy to cut to accommodate penetrations and edge detailing.

There were significant cost benefits compared to granular drainage. Deckdrain was assessed and approved by Mott MacDonald acting as the client’s engineer, and is BBA approved.

The ABG Service

ABG provided full technical support, including design calculations, drawings and installation advice.

Contact ABG today to discuss your project specific requirements and discover how ABG past experience and innovative products can help.

This scheme is an example of implementing an idea from the Highways England “Managing Down Costs” Toolkit.