HS2 has been given the green light and the project will go ahead at an estimated cost of £106bn but will need to look for significant cost savings. Saving cost and saving carbon can go hand in hand, especially when engineers look to change traditional methods of construction and so make best practice into standard practice.

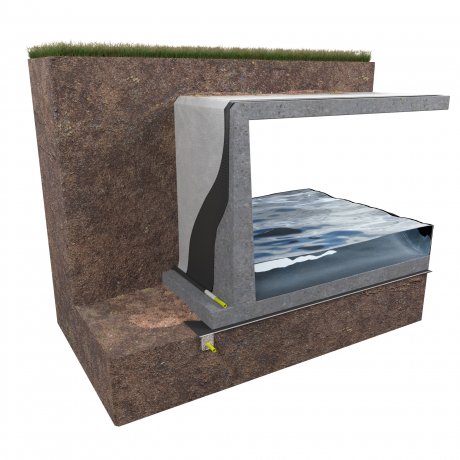

Significant, therefore, that instead of a traditional no-fines / hollow blockwork for relief of hydrostatic pressure behind buried concrete structures, ABG Deckdrain has been specified as part of HS2’s enabling works on retaining wall and bridge abutments. ABG Deckdrain is a high performance geocomposite drainage layer for relief of hydrostatic pressure behind buried concrete structures.

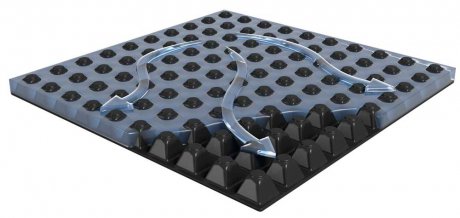

ABG Deckdrain is manufactured from a high strength flexible polyethylene cuspated core with a non-woven geotextile bonded onto one or both sides. The geotextile filters a wide range of soils, allowing water to percolate into the core to be rapidly transported away to a discharge point. The single cuspated HDPE core provides flow in all directions to give a drainage capacity rate 10 times greater than an equivalent layer of drainage stone or no-fines concrete.

The product is available in a range of flow capacities from 1 l/m/s to 95 l/m/s corresponding to thicknesses ranging from 4mm to 50mm, and can be supplied in a variety of roll sizes designed to suit site specific requirements. ABG Deckdrain is UK manufactured and BBA certified with a long history of use on Network Rail projects, offering a more sustainable replacement to the drainage backfill traditionally used by reducing the material movements and handling required in the process of excavation, backfill and enabling works.

The single cuspated HDPE core provides flow in all directions to give a drainage capacity rate 10 times greater than an equivalent layer of drainage stone.

CE 0799-CPR-30 & ISO 9001:2015

ABG Deckdrain is able to withstand the high loads associated with sub-surface drainage design including deep excavations and horizontal load applications. It resists the mechanical stresses imposed during installation and then on throughout its design life, with creep testing at compressive loads of up to 1000kPa giving a design life of 120 years. As a result, ABG Deckdrain is a highly effective structural drainage layer when used on cut and cover tunnels and green tunnels, acting as a durable protection layer for the chosen waterproofing system.

ABG has many other known applications of geocomposite drainage, Fildrain for example, that offer similar benefits for reducing settlement and speeding up consolidation of earth embankments.

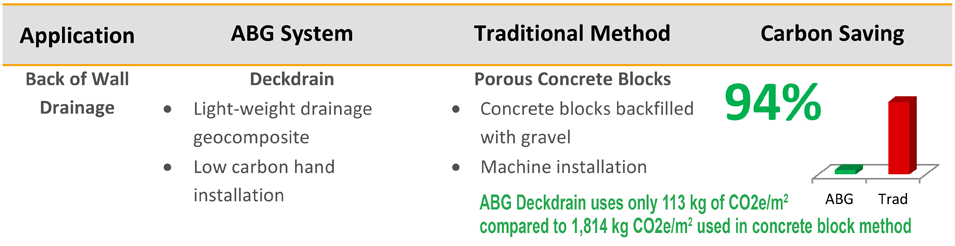

A recent ABG study estimates a carbon saving of 94% is possible from the reduction in weight and vehicle movements compared to using concrete blocks and stone fill at the back of tunnels, bridges and abutment structures. Due to the higher drainage properties, Deckdrain also often enables low grade recycled material from site to be used as backfill, further reducing transport emissions.

Carbon saving taken directly from the Costain case study (Wilson, 2018) which is a case study comparing the use of ABG Deckdrain with traditional solutions for drainage behind concrete bridge abutment retaining walls. The traditional solutions assessed were no-fines concrete (97% carbon saving) and hollow concrete blocks backfilled with gravel (92% carbon saving). The carbon saving stated is the based on hollow concrete blocks. The assessment in the case study discounted the removal of waste material, was based on actual distances to quarries/suppliers, and material quantities as assessed by Costain.